PRECURSOR

MICROSATELLITE

PROJECT DESCRIPTION

The PRECURSOR Microsatellite is a private non-profit

mission. Private people, research institutes and universities support this project.

The PRECURSOR is built with both commercial and open source resources. This

means hardware as well as software.

The mission of the PRECURSOR belongs to IOD/IOV (In Orbit Demonstration/In

Orbit Validation) activities.

LANDSPACE

Land

Space Technology Corporation Ltd. is a Chinese private aerospace enterprise

engaged in the R&D and operations of launch vehicles. Focusing on small and

medium scale commercial aerospace application market, Land Space is devoted to

the development of Liquid-fuel Rocket Engines (LREs) and low-cost commercial

launch vehicles with independent intellectual property rights. Land Space could

complete the system and unit design, manufacture, test and delivery with

highly-integrated design and innovation capability by a first-class technical

team, to provide the global market with standardized launch service solutions.

Land

Space always considers the technical innovation and market-orientation as the

core development task, and is confident to become a beneficial supplement of

China Aerospace, to continuously boost its future development.

LAUNCH VEHICLE

The PRECURSOR Microsatellite will be launched from

China on December 2024 from the Jiuquan Satellite

Launch Center (JSLC) in China. The launch vehicle

operator is the Chinese Start-Up LandSpace and the

PRECURSOR flight will be the second flight of the ZQ-2 launch vehicle. The ZQ-2

is a two-stage liquid propellant (LOX+LCH4) launch vehicle with a capability of

1.8 tonnes payload into 500 km SSO (Sun-Synchronous Orbit).

Figure 1: ZQ-2 Launcher

Figure 2: ZQ-2 Launcher Series

Figure 3: Mission Profile

Table

3: typical mission profile (ZQ-2 Block 1, 500km SSO)

|

Event |

Time (s) |

Altitude (km) |

Velocity (m/s) |

|

1st stage Ignition & Lift-off |

0 |

0 |

0 |

|

1st stage cut-off (MECO) |

151 |

69 |

1,960 |

|

2nd stage ignition |

155 |

74 |

1,928 |

|

Fairing separation |

212 |

140 |

2,733 |

|

2nd stage main engine cut-off (SECO) |

290 |

239 |

4,896 |

|

2nd stage Vernier cut-off (VECO) |

760 |

500 |

7,613 |

|

Payload deployment |

770 |

500 |

7,617 |

Table

4: Typical Separation Accuracy

|

Parameter |

Angle |

Rate |

|

Roll deviation |

≤0.7° |

≤0.3°/s |

|

Pitch deviation |

≤1.5° |

≤1.0°/S |

|

Yaw deviation |

≤1.5° |

≤1.0°/s |

Table

5: Injection Accuracy

|

Symbol |

Parameters |

Deviation |

|

△a |

Semi major Axis |

±5km |

|

△e |

≤1.5° |

0.003 |

|

△i |

≤1.5° |

±0.08 |

SATELLITE DESCRIPTION

The PRECURSOR Microsatellite doesn’t follow any kind

of standards like the CubeSat standard. The CubeSat standard has limitations and

for the mission objectives a customized solution is the best option. The

PRECURSOR satellite has the sizes 15x30x60 cm3. The weight is

approximately 17kg. The main experiment is a new generation propulsion system

for Orbital Plane Change (inclination) and/or Orbital Altitude Change and uses

green propellant. The PRECURSOR Microsatellite will validate several

technologies. The satellite is designed using Commercial electronics and

materials, Open Source Hardware and Open Source Software. This strategy allow

the quick implementation of this new satellite platform. Other experiments inside the PRECURSOR is a

multi-band GNSS receiver with a newly High-Performance GNSS Antenna for small

satellites.

Figure 4: Representation PRECURSOR Satellite in

orbit

ON-BOARD COMPUTER (OBC)

The OBC is based on the EFR32FG12 processor from

Silicon Labs. The OBC has four processors, one is the main and the other one

the backup. The processor was irradiated with Gamma rays and it was

demonstrated that this processor can be used in LEO orbit for several years.

Following are the most important characteristics of the OBC:

- Four ARM Cortex M4 with 40MHz.

- Operating supply voltage

between 3.7 – 4.0 V

- Internal FLASH memory of 1MB

- RAM size of 256 kB

- Interfaces available are I2C,

SPI and UART

- 46 GPIOs

- Operating temperature in a

range between +20°C to +85°C

- Data Bus Width of 32 bit

- ADC with a resolution of 12 bit

Figure 5: Small size computer

OPERATING SYSTEM

The PRECURSOR Microsatellite uses RODOS (Realtime Onboard Dependable Operating

System) as operating system.

RODOS was developed at the German Space Agency (DLR) and is a derivate from the

BOSS operation system, which is used in the micro-satellite program DLR's.

Satellites using this operation system are BIRD and TET-1 and BiROS. RODOS is ideal for Telemetry and Telecommands

tasks. It is light to migrate to other systems.

RODOS is an open source software and is implemented in C++ and has also

following features:

- object-oriented C++ interfaces,

- ultra-fast booting

- real time priority controlled

pre-emptive multithreading,

- time management (as a central

point),

- thread safe communication and

synchronisation,

- event propagation

Figure 6: RODOS OS Logo

POWER MODULE

The power module consists of a set of solar cells,

Lithium batteries and the electronic to regulate and distribute the power in

the system.

The Power Conditioning Distribution Unit (PCDU)

distributes it internally to the energy consumers or to the batteries.

The Maximum Power Tracking (MPPT) charge controller

allow to maximize the energy extraction generated by the solar panels.

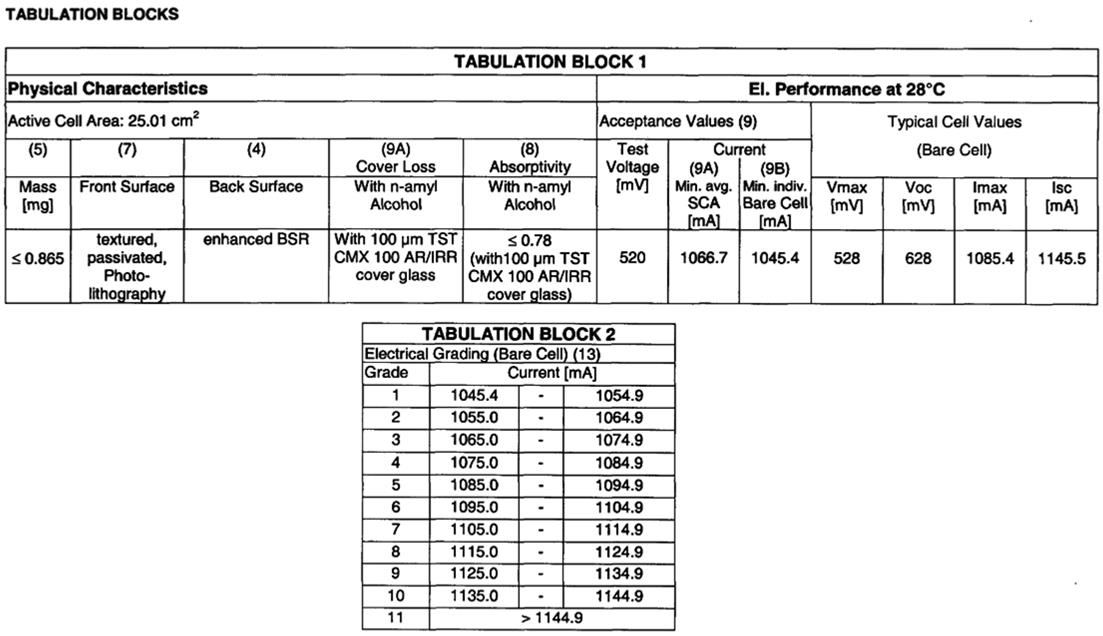

Solar Cells

The solar cells are commercial and has the size of 125x41,6

mm. Each cell is equipped with 12.5µm Ag interconnector welded to the solar

cell in-contact. The solar cell is covered with 0,7 mm thick Borosilicate glass

with the size of 41,6x125 mm.15mm bonded by use of silicone adhesive DC93500.

The cells have an efficiency of around 23%, with a voltage of 0,5V and 1,2W per

cell.

Figure

7: PRECURSOR Solar Cells

Figure

8: Solar Cells Characteristics

Batteries

In order to increase the lifetime of the batteries a properly reload cycles is

essential. The power electronic will configure automatically the best reload cycles

and power consumption, monitoring constantly the status level of the batteries.

Each cell has following characteristics:

- Nominal voltage: 3.6 V/cell

- Nominal capacity: 1600 mAh /cell

- Operating temperature: -25°C to

55°C

The charge and discharge process will be controlled

with a charge controller IC, which is equipped with a MTTP (Maximum Power Point

Tracking) control unit.

The power module has a power capacity of 10Ah (11V).

Figure

9: Lithium Ion Cell High Energy (Source EAS)

COMMUNICATION MODULE

It consists in a modem and transceivers which converts

the digital data in an analogue signal. The data to be transmitted will be provided

by the OBC, which administrates the data distribution and encapsulation. The

standard CCSDS will be used for encapsulation purposes. The communication

module transmits and receives in VHF, UHF, L-Band and S-band.

Following transceiver will be used:

VHF/UHF Transceiver

The selected transceiver will be tested in order to see the radiation

robustness. Thermal-Vacuum and Outgassing tests will be also included.

Characteristics of the transceiver:

- Data rate: 256 kbps

- Power transmission:0,1-2W

Uplink Frequencies

·

435.0125-435.0375

·

436.17875-436.19125

Downlink Frequencies

·

145.9625-145.9875

·

144.01-144.02

L-Band

Receiver

Uplink Frequencies

·

1261.25-1261.75

·

1260.11875-1260.13125

S-Band

Transmitter

Having a camera as payload is important to transfer data

in a higher data rate as is possible by the UHF transceivers. For this reason

for the remote sensing experiment S-Band transceiver is recommended. Following

modules characteristics are considered:

- Data rate: 1,06 Mbit/s

- Power transmission: 2 W

- Error correction: 32 bits CRC

Downlink Frequencies

·

2400.6-2401.1

·

2400.84375-2400.85625

ITU LICENSE

You can find the ITU license under following link:

![]()

THERMAL CONTROL

The thermal behaviour of some sensible components like

the batteries and solar cells will be monitored by using temperature sensors.

The thermal sensors and the heaters will be controlled by the OBC.

Temperature Sensors

The temperature sensor PT1000 will be used in the PRECURSOR. Such sensor is

commonly used as thermometer in microcontrollers but also often in satellites

Heaters.

The Heaters will be also used specially for batteries conditioning. The

selected heaters have high quality, low power consumption and small sizes. In

that way the temperature can be regulated in a range for save operation of

sensible electronic, typically between -20°C and +60°C.

Heat Sink

For thermal control one side (30x60 cm2) of the satellite structure will point

constantly to the Earth. This side will be used as heat sink and it will

dissipate the excess warmth.

ATTITUDE SYSTEM

The Attitude subsystem will consist of two different

parts. The first one will be a sensor set of Sun sensors, Magnetometers,

Accelerometers and Gyroscopes for orbit determination.

The second part will be built with a set of actuators, consisting of magnetic

coils and micro-reaction wheels.

With the mentioned configuration the Attitude system fulfils a required

accuracy of +/- 5°. Further, the Attitude System will have its own

microcontroller to manage the complexity of the required calculations for

attitude control.

The attitude system will have following characteristics:

- Size: 9,5x9,5x10cm

- Mass:1000g

- Power consumption: 0,5-1,8W

- Attitude Knowledge: ±5°

- Pointing accuracy: ±6°

- Sensors: Accelerometers

(3-axis); Gyroscope (3-axis); Magnetometer (3-axis)

- Actuators: 3 reactions wheels

(torque 0,087mNm / 1,5mNms)

Figure

10: Multi-sensor Board

PAYLOAD

In the PRECURSOR mission many technologies will be

tested but following main experiments are the principal payloads:

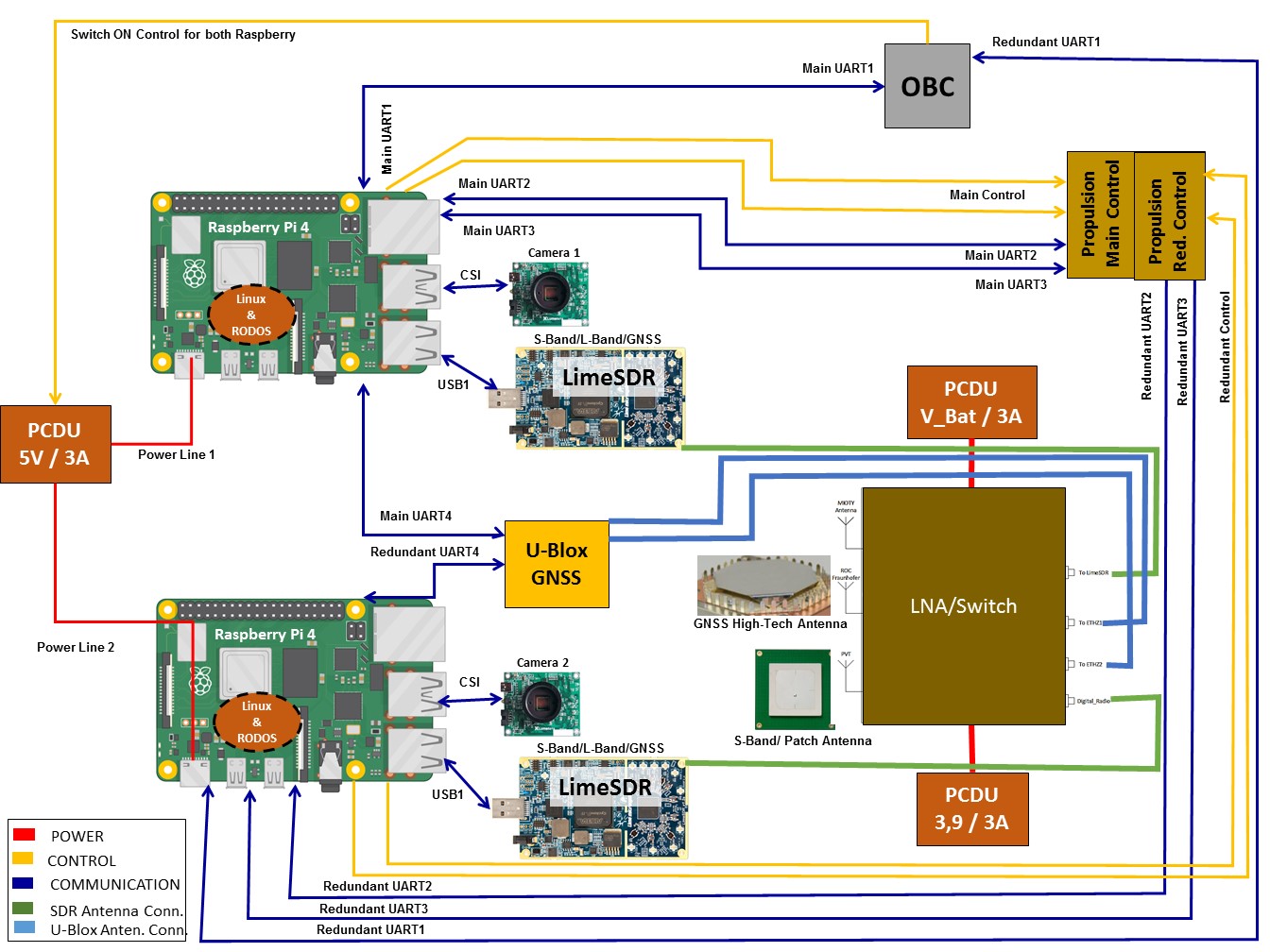

Payload

Computer

The payload

computer is based on two Raspberry Pi 4. One is the main computer and the other

is the redundant computer. Both RPi-4 have the same software and have the

following functions:

·

Communication

with the on-board computer.

·

SDR Radio

Control (Multifunction)

·

U-Blox GNSS receiver

·

S-band transmitter

·

L-band

receiver

·

USB camera

control

Figure 11: Raspberry Pi 4 installed

in PRECURSOR

Figure 12: Payload Block Diagram

Propulsion

System

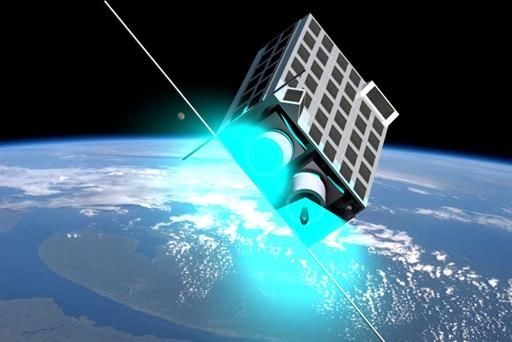

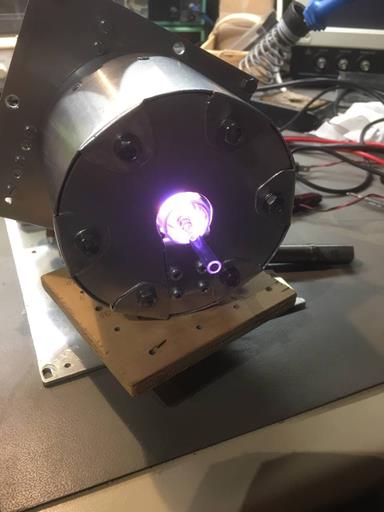

The main payload consist in a new generation propulsion

system. This propulsion system was designed for:

- Orbital Plane Change

(inclination)

- Orbital Altitude Change

This is the first time that such engine will be tested

in space. The propulsion system uses green fuel and has a maximal thrust of

2.5mN. The fuel volume is 1700 ml.

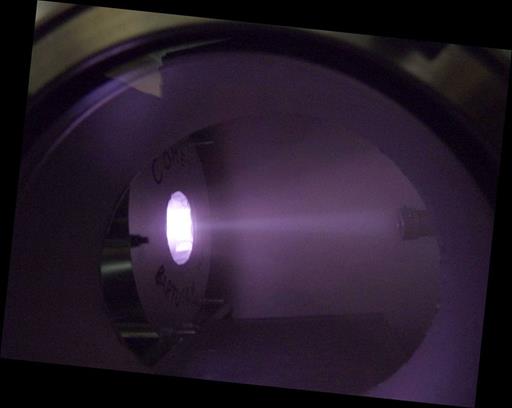

The thrust engine is based on the Magnetic Field

Oscillating Amplified Thruster (MOA). This thruster is able to accelerated

charged gases to extremely high velocities generating a high energetic plasma

jet.

During the mission several manoeuvres will be achieved

with the propulsion system. The exact positions during the manoeuvres will be

tracked and registered on-board with the GNSS receivers and the raw data will

be processed on the ground.

Figure 11: PRECURSOR Thrusters activation

Figure 12: Fuel tanks

Figure 13: Thruster magnetic field intensity

Figure 14: Plasma Test

Figure 15: Magnetic Momentum Test

Figure 16: Thrust Test in the TV Chamber

Figure 17: TV Chamber and Test Setup

GNSS

Receiver 1

The GNSS payload consists of a GNSS receiver board

equipped with four u-blox ZED-F9P receivers,

connected to two GNSS antennas located on the outer surface of the satellite.

It is contributing to the mission objectives by determining the satellite

position, velocity and time (PVT). After downloading the data to ground, in

post-processing the GNSS code and carrier phase measurements are preprocessed and a reduced-dynamic orbit is fit into the

kinematic positions for orbit analysis. This will allow for the detection of

changes in the orbital elements and thus, to assess the performance of the

propulsion system onboard the PRECURSOR satellite.

After the primary mission goal has been achieved, the GNSS payload board will

be used for testing the radio occultation capability of the GNSS receiver.

Characteristics of the receiver board

•

Size: 96 x 90 x 22 mm

•

Mass: 250 g

•

Connectors: SMA, Gecko 10 pin

For validation of the GNSS-based PVT solution, a

reflector array is installed on the satellite. It consists of three corner

cubes glued in a custom made aluminum structure.

Mounted on the nadir-looking face of the satellite, it allows

satellite-tracking from a global network of laser ranging stations and

therefore, enables precise orbit determination on the sub-dm

level during dedicated measurement campaigns.

Team ETH:

Gregor Moeller, Flavio Sonnenberg, Alexander Wolf, Markus Rothacher

Figure 18: Case of the High-Precision GNSS Receiver Module

Figure 19: GNSS Receiver Board with 4 u-blox

ZED-F9P Receivers

Figure 20: Laser Retro-Reflector

Figure 21: Retro-Reflector Mounting

GNSS

Receiver 2

A LimeSDR receiver

A LimeSDR receiver will be

used as GNSS receiver. The application software is based on open-source code.

The receivers have a high precision clock with following characteristics:

- Frequency 10.000000MHz

- Stability 0.1 - 0.5 ppm

Figure 22: LimeSDR Radio

Receiver (Source: limemicro.com)

A second SDR

will be used as backup system. In this case we will use an Adalm-Pluto

and it will be connected to a Raspberry Pi 4 too.

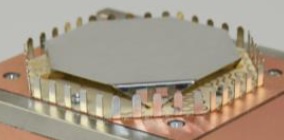

GNSS Antenna

The GNSS antenna is a new generation antenna designed

for small satellites. The antenna has following characteristics:

- Size: 10x8.3x1 cm

- Mass: 20g

- Passband: 1160 - 1300 MHz and

1525 - 1610 MHz

- Polarization: RHCP

- Passive zenith gain: L1, E1, G1

>1.5 dBic and L5, L2, E6 >0 dBic

- Passive horizon gain: >-7 dBic

Figure 23: PRECURSOR GNSS Antenna

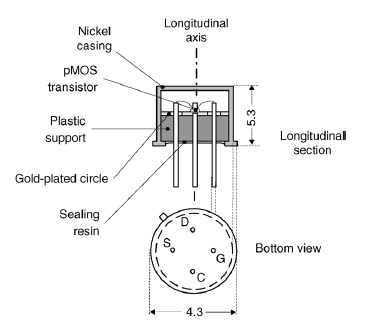

RADIATION

SENSORS

In this

experiment commercial transistors will be used as radiation sensors. The

selected transistors are manufactured with standard low-power enhancement mode

lateral pMOS technology. Designing a low-cost

hand-held measurement system using this pMOS as the

sensor would have a clear advantage due to the lower cost incurred by a

standard technological process.

Figure 24: Transistor

3N163 as radiation sensor

STRUCTURE

To protect the electronic inside against radiation a

robust structure helps to reduce the radiation dose and extend the lifetime of

the electronic parts.

The design of the structure is customized and compliant with mission

requirements, where following types of duralumin will be used for the walls:

5052 H32 and 6061 T6. The solar cells will be attached to the structure sides.

Small pieces will be printed and with PEEK material manufactured.

Figure 25: PRECURSOR Structure

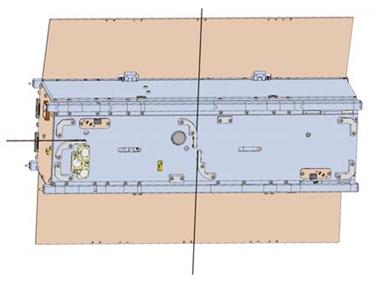

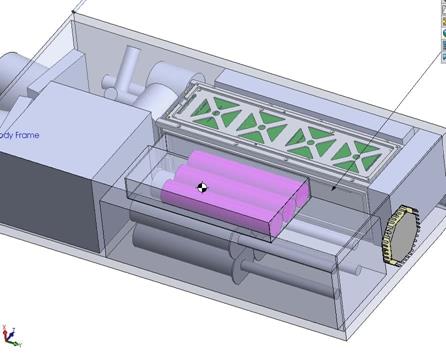

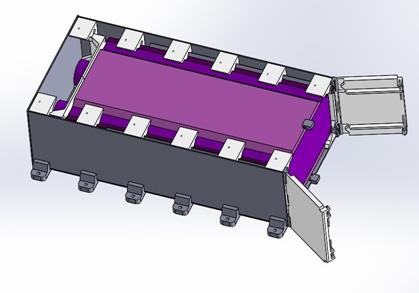

PAYLOAD CONTAINER DEPLOYER

For the satellite a customized deployer

is designed. The deployer will be manufactured with

Duralumin 7075 T6, and 3D printed parts.

Figure 26: PRECURSOR Deployer

ENVIRONMENTAL TESTS

The payload has to absolve an acceptance

qualification. In this process will be proofed that the payload can withstand

the flight on the ZQ-2 without damaging other payloads.

Following environmental tests will be achieved prior

the launch:

- Vibration Sinusoidal

- Vibration Random

- Shock Test

- Outgassing

- Thermal Vacuum

Some tests will be achieved at System level or at

module level.

·

VIBRATION

The major stress during the flight will be generated from the launch

vehicle vibrations. It must be guaranteed that the payload will not be

destroyed during the launch.

o

SINE VIBRATION

The

table 6 lists the experimental conditions for low frequencies sine vibration

from

5Hz

to 100Hz, which are used to simulate the transient and stationary random

vibration of a launcher.

Table

6: Low Frequency Sine Vibration Scan Test Condition

|

Position |

Frequency Range(Hz) |

Acceptance Level |

Identification

Level |

|

Payload

Bracket |

5~10 |

2mm |

3mm |

|

10~100 |

0.8g |

1.2g |

|

|

Scanning

Rate R |

4.0Oct/min |

2.0Oct/min |

|

o

RANDOM VIBRATION

The

table 7 gives the test conditions of random vibration at high frequencies

ranging from 20 Hz to 2000 Hz, which can be used to simulate the transient and

stable random vibration of a rocket.

Table

7: Payload Interface Random Vibration Levels

|

Position |

Frequency Range (Hz) |

Acceptance Level |

Identification Level |

||||

|

Power

Spectral Density (g2/Hz) |

Duration

of

Test Runs (min) |

Total

Mean Square Root(g) |

Power

Spectral Density (g2/Hz) |

Duration of

Test Runs (min) |

Total Mean Square Root (g) |

||

|

Payload

Bracket |

20~150 |

3dB/Oct |

1 |

6.94 |

3dB/Oct |

2 |

10.41 |

|

150~800 |

0.04 |

0.09 |

|||||

|

800~2000 |

-6dB/Oct |

-6dB/Oct |

|||||

·

SCHOCK

The

impact experiment condition (shock response spectrum Q=10) is shown as the

table 8. The response acceleration time history in three vertical directions at

the bottom of the specimen must be measured during the test.

Table

8: Shock Response Spectrum (Q=10)

|

Position |

Frequency Range(Hz) |

Acceptance Level |

Identification

Level |

|

Satellite |

50~1000 |

9dB/oct |

9dB/oct |

|

1000~8000 |

3000g |

4500g |

|

|

Semi-sine

vibration test: peak value of the accelerated velocity is 200g;PW is 6ms with X

direction; Repeat the test 3 times for each direction. |

|||

·

ACOUSTIC

Acoustic

condition is detail in table 9.

Table

9: Payload Acoustic Environment

|

1/3 band Central frequency

(Hz) |

1/3Sound Pressure

Level / dB in band Width |

|

Inside the Fairing |

|

|

25 |

111 |

|

31.5 |

113 |

|

40 |

115 |

|

50 |

120 |

|

63 |

125 |

|

80 |

127 |

|

100 |

129 |

|

125 |

130 |

|

160 |

131 |

|

200 |

131 |

|

250 |

131 |

|

315 |

132 |

|

400 |

132 |

|

500 |

132 |

|

630 |

131 |

|

800 |

131 |

|

1000 |

129 |

|

1250 |

126 |

|

1600 |

123 |

|

2000 |

121 |

|

2500 |

120 |

|

3150 |

119 |

|

4000 |

117 |

|

5000 |

115 |

|

6300 |

114 |

|

8000 |

112 |

|

SPL |

142 |

·

EMC

The

Electromagnetic radiation for the radio equipment on the launch vehicle and

also the launch site cannot exceed the requirement shown in the table10.

Table

10: EM radiation of the rocket and launch site

|

Frequency(MHz) |

Intensity(dBμV/m) |

|

0.01~0.05 |

80 |

|

0.05~3 |

90 |

|

3~30 |

70 |

|

30~550 |

65 |

|

550~750 |

103 |

|

750~2200 |

90 |

|

2200~2300 |

138 |

|

2300~1000 |

90 |

|

10000~ |

90 |

GROUND SEGMENT

The ground segment consists in radio-amateur ground

stations, which allow the effective operation of the mission. For commanding

two stations will be used. For downlink the telemetry if open and free for the

radio-amateur community. For the communication issues the project has the

support from AMSAT-DL.

Principal capabilities and features of the ground segment:

- All stations have the similar

hardware and software configuration

- Remote or autonomous (without

staff) control

- Collected data can be

transferred between stations

- Uplink with two station

possible

- Downlink for all support

stations

- The duration of one pass takes

around 10 min

- Number of contacts in average

per day and per station is 4 in average

- Data download in average of 703

KB (UHF) per contact

The core components of the PRECURSOR ground station

are:

- Transceiver ICOM IC-9100 (VHF

and UHF)

- Power supply for the

transceiver PS-125.

- Two pre amplifiers (one for

VHF, other for UHF)

- Antenna rotor Big-RAS

- Two Yagi antennas, one for VHF

(2 m), other for UHF (70 cm)

- Cables and connectors

- Personal computers with network

adapter

Figure 27: AMSAT-DL 20m antenna in Bochum

MISSION OPERATIONS

A group of 4 Operators (licenced radio amateurs) will

be available for this project.

The mission operations team will manage the schedule of the satellite contacts,

depending on the payload activities.

The mission operation prepared is based on the ESA standards for flight control

organisation and will have the following phases:

Pre-Launch phase

Before satellite will be launched

the team will be trained for all phases of the mission using a duplicate of the

most important satellite parts. This twilling system will build a simulator

helping to restage all the cases of the mission to operate the satellite. The

team will be also trained to manage all routine activities and emergency cases.

In this phase all necessary procedures and documents will be written and

validated.

LEOP phase

During this

critical phase the satellite will be in contact with all possible ground

stations in order to initialise all the subsystems. Test transmissions with the

ground stations and each function of the satellite will be checked. All the

subsystems will be configured for the routine operation. In this phase the

operations team will work with the bus only but not with the payloads. The

operation service of 24 hours begins on shifts. The organization of the flight

control team will be redundant following the ESOC typical organisation for a

LEOP.

Commissioning phase

In

this phase the operations team will work with the payloads. The payloads will

be switched, checked and configured. After that the calibration of the

instruments will be achieved. During this phase is necessary to be in contact

with the instruments responsible in case of malfunctions.

Routine phase

During this phase the team will

keep the 24 hours shift work but the activities will be reduced and for any

anomaly an On-call service will be available. The satellite will keep the

nominal mode and the instruments (payload) will collect science data. In the

scheduled contacts the science data will be down-linked, stored and forwarded.

Recovery

In case of an emergency situation and the satellite is

not able to go back to the nominal mode due to several errors the team has to

execute emergency procedures and have to prepare the commands to recover the

spacecraft.

For the PRECURSOR mission operations following

activities are planned:

- Daily downlink of the

housekeeping telemetry

- Daily downlink of the science

data

- Manoeuvres with the propulsion

system

- Experimental measurements with

the GNSS receivers

- Downlink of the GNSS

measurements raw data

- Post-processing of the raw data

TEAM

Jaime

Jaime Estela is an electronic engineer born in

Lima-Peru. He worked at the German Space Operations Center

of DLR in Oberpfaffenhofen for 11 years. In this

period he gathered experience in satellite operations and systems engineering

and supported several LEO orbit satellite missions like Terrasar-X,

Tandem-X, Prisma A & B, Grace 1 & 2, CHAMP,

BIRD, TET and was also involved, as Ground Segment Engineer, in the ESA project

Columbus, space laboratory onboard the ISS,.

Furthermore

he has supported CubeSat projects developed by Universities. He supported the

project QB-50, an international constellation of 50 CubeSats

which will study the higher ionosphere in a low Earth orbit and during its

re-entry as suborbital research platform.

Jaime is a

supporter of the NewSpace initiative and contributes

to this space movement actively with new concepts, ideas, products and

services.

Alex

Dr. Alexander Popugaev received the M.S. degree (with

honours) in radio engineering from the Vladimir State University, Russia, in

2004, and the Dr.-Ing. (Ph.D.) degree (summa cum

laude) from the Technical University of Ilmenau,

Germany, in 2013.

Since 2004,

he has been with the Fraunhofer Institute for

Integrated Circuits IIS, Germany.

During his

over 15 years long tenure at the RF and Microwave Design Department, later RF

and SatCom Systems Department, Dr.

Popugaev worked his way up from Research Associate to

Chief Scientist.

Due to his

successful long-time R&D activities in the field of customer-specific GNSS

antennas, Dr. Popugaev

moved in 2020 into the Satellite Based Positioning Systems Department. His

current position is Business Development Manager for GNSS Antennas.

Dr. Popugaev has authored and

co-authored several scientific papers and book chapters and has received

several patents.

Tobias

Tobias

Bartusch is an electrical engineer since 2000 (FH Augsburg) and physicist

(Univ. Augsburg) since 2006. He gained theoretical and practical experience in

many space projects in different companies since 2006 (neutralizers and

RF-multi staged magneto-plasma thrusters, boxes / modules for various

customers, atomic clocks, timing systems and analog

space design, AIT and Systems Engineering). In addition, he has developed high

vacuum systems (tubes, electron emitters, plasma sources and measurement equipment)

and vacuum chambers. He is experienced in the development of vacuum COTS

equipment and space materials / high vacuum materials such as coatings for

thermal radiators, AtOx resist, PTFE, and other. In

the Precursor project, he is the responsible engineer for AIT, thermal design,

deployment box, solar panels, charger, electrical thruster, some power

converters, parts of the antenna integration and test. He is also a radio

amateur (DH2MBT) and member of the DARC and AMSAT-DL. The satellite will be

integrated in his workshop and laboratory which has the capability to perform

all necessary steps.

Miguel

Miguel Ángel Carvajal Rodríguez: Tenured

Professor of the Department of Electronics and Computer Technology, CITIC-UGR,

IMUDS-UGR, University of Granada, Granada, SPAIN

Alberto

Alberto José

Palma López: Full Professor of the Department of

Electronics and Computer Technology, CITIC-UGR, University of Granada, Granada,

SPAIN

Gregor

Gregor

Moeller is a senior scientist and lecturer at the Institute of Geodesy and

Photogrammetry at ETH Zürich with focus on high-precision GNSS, nanosatellite

orbit determination and atmospheric remote sensing.

Andrés

Electrical

Mechanical Engineer from the National University of Engineering of Peru, with

experience in development of space projects at undergraduate level in events

held by CNES FRANCE: C'SPACE 2019 with pico

satellites for meteorological applications and in C'SPACE 2022 with

experimental rockets for tropospheric missions. He participated in the development

of a mini autonomous vehicle for ground reconnaissance missions at the ARLISS

event held by the NATIONAL ASSOCIATION OF ROCKETRY USA.

In the

Precursor mission, he performed the modal analysis and thermal simulation of

the satellite structure.